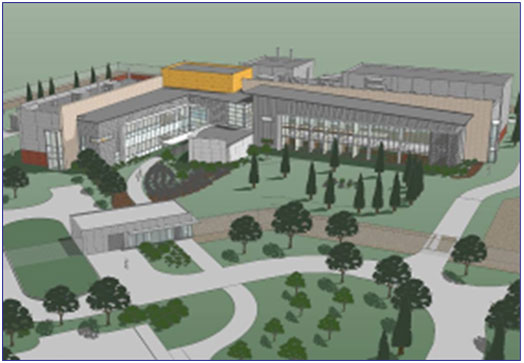

Project Description

The purpose of this subcontract is to complete engineering, complete the excavation performed by others, prepare the subgrade, and construct the foundations and the Superstructure for the Central Reference Laboratory (CRL) building. Also, review and complete the remaining engineering for the Potable Water Storage Tanks located west of the CRL Building. Design and Furnish all Underground Utilities in Under slab and outside the Building. Design and Furnish Underground Fuel Oil Tank. Upon construction of the foundations and Superstructure, and the water tanks, the buildings will be completed and finished for operation by others.

Project Location

The CRL site is located in the eastern part of Tbilisi approximately three (3) kilometers form the airport, and approximately eighteen (18) kilometers from the Tbilisi Freedom Square, in Alekseevka settlement, within the property owned by the Ministry of Defense (MOD). The site is fairly flat and the elevations range between 510 meters to 517 meters above the sea level.

Services Provided

- Mobilization of all personnel, equipment

- Provide Engineering services and Preparation of all required submittals

- Performing civil surveys and establishing existing topography and conditions of the site

- Excavating and disposal of unsuitable subsurface material

- Setting up a Compaction Test Pads to establish the minimum number of passes of a specific type of compaction equipment proposed for compaction of subgrade and engineered Structural Backfill Material (SBM) for Quality Control

- Preparing the subgrade, Compacting the subgrade, and compaction testing of the subgrade

- Installing Polyvinylchloride (PVC) liner on the subgrade and on top of the SBM

- Supplying and installing SBM

- Performing Plate Bearing Load Test after installation of SBM

- Selecting and identifying the source for obtaining engineered SBM

- Identifying sources of coarse and fine aggregates and testing of aggregates for concrete

- Developing mix designs for concrete and mortar

- Procuring, furnishing, and installing rebar and associated accessories

- Supplying, furnishing and installing structural steel embeds, and accessories

- Procuring and furnishing embedded piping and other components

- Forming, placing rebar, pouring concrete for foundation superstructure, testing and curingconcrete

- Installation of damp proofing, waterproofing, thermal insulation

- Furnishing and installing roofing system

- Furnishing services of an independent onsite Material Testing Laboratory

- Preparing As-Built Drawings and maintaining project records

- Construction of water storage and oily water filtration facility

- Site Cleanup and Demobilization